Control System Lab

“We are OEM and NSIC Approved in more than 300 categories on GEM.This item is available on GEM for purchase pan-India”

Control System Lab

“We are OEM and NSIC Approved in more than 300 categories on GEM.This item is available on GEM for purchase pan-India”

TTL circuit for single stepping and free run mode with frequency generator <10-100 Hz Wobble mode

Direction selector

LED indicators for phase sequence observation

12V, 1A/phase, 2.0 kg/cm torque, 1.8 degree stepper motor, uP

interface

Calibrated dial for position monitoring

Position pick up by servo potentiometer

IC regulated power supply for complete circuitry

Supporting literature with patch cords, 220V mains operated.

Study of Synchro Transmitter / Receiver

Two dials for input/output angular displacement

Knob with large pointers on transmitter and receiver

Sockets for rotor (R1, R2) and stator (S1, S2, S3) on panel

Built in isolated power supply for both

Attenuated output on sockets for view of signal observation on

CRO

Supporting literature with patch cords

220V mains operated

Two phase AC Servo Motor (2500 RPM).

Electronic speed sensor with RPM display on panel meter.

Ammeter for load current.

DC Motor for loading.

Torque calculation from back emf.

Speed controller for motor.

Isolated supply for motor.

User’s Manual with patch cords.

220 V AC operated.

To study of potentiometer as error detector element

Two Full 360 degree rotation servo- potentiometers with

1 degree resolution

IC regulated DC excitation for both potentiometers

AC excitation at 400 Hz approx.

Built in demodulator circuit

3.5 digit DVM for carrying measurements

IC regulated power supply for rest of the circuitry

Complete with instruction manual and patch cords, 220V mains operated.

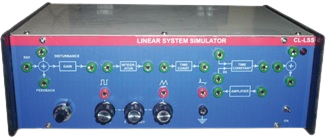

Study of simulated linear systems

Simulated blocks configurable as first, second and

third order systems

Disturbance adding facility at input and output

Signal Sources

Square wave : 20-80 Hz, 0-2 Vpp continuously variable

Triangular wave : Similar to square wave both in frequency and amplitude

Integrated triangle wave fixed amplitude

Built in IC regulated power supply

Complete with detailed instruction manual and patch cords,

220V mains operated

Study of DC position Servo

Position control of a 12 volt, 1 Amp DC geared PM motor (50/60

RPM)

Calibrated dials with 1 degree resolution for reference and output position

Two 360 degree Servo-potentiometers

Built in step signal

Built in waveform capture/display card for study dynamics

3.5 digit digital voltmeter

IC regulated DC power supplies for circuitry

Supporting literature for experiments with patch cords,

220V mains operated

Study of lag, lead and lag-lead

Second order simulated systems

Study of All pass filter

Lag, lead and lag – lead compensating circuits

Gain compensating amplifier with calibrated dial

Signal sources

Sine wave : Continuously variable in two decades (10-1000

Hz) with 0-8 Vpp amplitude

Digital phase angle meter 0-180 degree (optional)

Complete with patch cords and detailed literature, 220V mains operated

Feedback control of light intensity

Study of inherent non-linearties- sensor, lamps

PI control

Dynamic response display

Experiments & specifications :

Characterization of light panel and light sensor blocks

Study of a practical single loop feedback control system which includes :

– Disturbance study

– Error monitoring

Performance improvement through P-I control

Evaluation of dynamic behaviour

Seven lamps 6V/300mA

5 Hz square wave and triangular wave for dynamic response study

Switch selectable PI-Controller

Built-in 3.5 digit DVM

Built-in IC regulated power supplies

220 +/- 10%, 50 Hz mains operation

Detailed literature and patch cords included

Study of speed control of DC motor in open and close loops

Speed control of 12V, 4W, permanent magnet DC motor

Speed range upto 3000 RPM (typical)

Electronic techogenerator for feedback

Non-contact eddy current break for load

4 digit RPM counter

3.5 digit digital voltmeter

Built in regulated power supply

Detailed instruction manual with patch cords, 220V mains operated

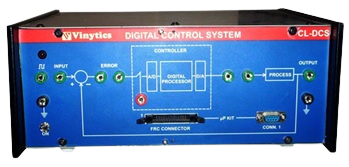

Digital Controller implementation on uP-kit

Simple Op-amp based analog plant

CRO display of response

Design and test new algorithms

Experiments :

Indentification of the controlled process

Study of sampling period variation

Designing P,PI,PD and PID controllers

Advanced algorithms implementation

Features and specifications :

Second order simulated process (analog process)

Built-in D/A and A/D circuits (8-bit)

8085 based uP kit as digital controller with user software in

8K EPROM

16-bit arithmetic for algorithmic calculations

16 built-in levels of P, I and D gains each.

Complete flexibility for the user to develop own software

Square wave test input (internal)

IC regulated internal built in power supplies

220V +/- 10%, 50Hz mains operation

Detailed literature and patch chords included

Essential accessory – a CRO

Fast compact oven upto 90 degree C

Variety of control actions

Digital temperature readout

Solid state temperature sensor

Experiments :

Identification of the oven parameters

Study of ON-OFF temperature control (with adjustable relay characteristics)

Study of P, PI, PD and PID controls having adjustable coefficients

Features and Specifications :

Temperature controller with facilities for P,I,D and relay control blocks

Operating temperature : Ambient to 90 degree C

Separate control for P,I,D channel gains

Two settings for relay hysteresis

Fast 25W oven fitted with IC temperature sensor

Digital display of set and measured temperature on a 3.5 digit built in DVM

Buffered output for recorder

IC regulation in controller circuit power supplies

220V +/- 10%, 50 Hz main operation

Supporting literature and patch cords included

No accessories required

Study of AC position servo motor.

Two precision servo-potentiometers full 360 degree rotation

Calibrated dials for command and output position with 1 degree resolution

Motor controller circuit (thyristorized)

110 volt two phase AC servo motor (60 RPM synchronous)

Waveform capture/display card

220 Vac mains operation

Isolated supplies for motor, control circuit and card

Supporting literature with patch cords

220V mains operated

Address List

- 12, Truck Market, Opp. R.K. Hospital, Near Mother Dairy Red Light, Pandav Nagar, Delhi-110092

-

+91 9899899166

+91 9871600331

+91 9868039427 -

vinyticsindia@gmail.com

www.vinytics.in