Electrical Drive Lab

“We are OEM and NSIC Approved in more than 300 categories on GEM.This item is available on GEM for purchase pan-India”

Electrical Drive Lab

“We are OEM and NSIC Approved in more than 300 categories on GEM.This item is available on GEM for purchase pan-India”

Aluminium Profile Modular System consisting of different type of modules.

Educational Bench Top Model with schematic / block diagram of the test circuit engraved on the panel.

Test points & measurement points brought out

and connected to 2mm plastic & BT15/30 terminals circuit setup for testing through

in reconnections of patch cards.

Complete illustrated manual covering brief theory of Equipment along with technical details and experimental procedures,

Connection diagrams will be supplied with experimental set up.

Technical Specifications:

1) Digital Meters: Voltage (0-300V) & Current Measurement (0-10A)

2) Digital RPM counter

3) Double Pole MCB

4) LED Indicators

5) D.C. MOTOR:

Type: DC Motor, separately excited, screen protected, horizontal foot mounted, fan cooled, Capacity: 1 HP,Winding: Shunt wound, R.P.M.: 1500, Volts. : 230,Insulation:

Class ‘B’, Armature and field sockets brought out to connect to the panel

6) FIRING CIRCUIT:

Line Synchronizing Op-Amp based triggering circuit

Firing Pulse Generator Digital type

Potentiometer used to vary the triggering circuit

Pulse output terminals

1:1 Pulse Transformer 1 KVA

Step Down Transformer Firing Circuit.

7) POWER CIRCUIT:

Four SCR’s (600V/12A)

Suitable RC Snubber Circuit

Free Wheeling Diode

8) LOAD

Consist of resistive load (100Wx1)

Lamp Holder

Lamp 250 Volts or

Inductive Load

9) 1:10 Attenuator for RRO

10) Isolated 220V AC for CRO

11) Field & armature terminals for DC shunt motor

12) Uncontrolled DC output 220V for field voltage of DC motor

Aluminum Profile Modular System consisting of different type of modules.

Educational Bench Top Model with schematic / block diagram of the test circuit engraved on the panel.

Test points & measurement points brought out

and connected to 2mm plastic & BT15/30 terminals circuit setup for testing through

in reconnections of patch cards.

Complete illustrated manual covering brief theory of Equipment along with technical details and experimental procedures,

Connection diagrams will be supplied with experimental set up.

Technical Specifications:

1)Digital Meters: Voltage (0-300V) & Current Measurement (0-10A)

2)Digital RPM counter

3)Double Pole MCB

4)LED Indicators

5)D.C. MOTOR

Type: DC Motor, separately excited, screen protected, horizontal foot mounted, fan cooled, Capacity: 1 HP,Winding: Shunt wound, R.P.M.: 1500, Volts. : 230,Insulation:

Class ‘B’, Armature and field sockets brought out to connect to the panel

FIRING CIRCUIT:

Line Synchronizing Op-Amp based triggering circuit

Firing Pulse Generator Digital type

Potentiometer used to vary the triggering circuit

Pulse output terminals

1:1 Pulse Transformer 1 KVA

Step Down Transformer Firing Circuit.

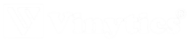

POWER CIRCUIT

Two SCR’s (600V/12A)

Suitable RC Snubber Circuit

Two Diodes(600V/6A)

LOAD

Consist of resistive load (100Wx1)

Lamp Holder

Lamp 250 Volts or

Inductive Load

1:10 Attenuator for RRO

Isolated 220V AC for CRO

Field & armature terminals for DC shunt motor

Uncontrolled DC output 220V for field voltage of DC motor

Aluminum Profile Modular System consisting of different type of modules.

Educational Bench Top Model with schematic / block diagram of the test circuit engraved on the panel.

Test points & measurement points brought out

and connected to 2mm plastic & BT15/30 terminals circuit setup for testing through

in reconnections of patch cards.

Complete illustrated manual covering brief theory of Equipment along with technical details and experimental procedures,

Connection diagrams will be supplied with experimental set up.

Technical Specifications:

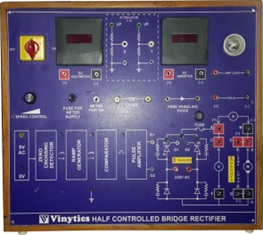

1)Digital Meters: Voltage & Current Measurement

2)Digital RPM counter

3)Double Pole MCB

4)LED Indicators

5)D.C. MOTOR:

Type: DC Motor, separately excited, screen protected, horizontal foot mounted, fan cooled, Capacity: 1HP,Winding: Shunt wound, R.P.M.: 1500, Volts. : 230,Insulation: Class ‘B’, Armature and field sockets brought out to connect to the panel

6) FIRING CIRCUIT:

Potentiometer as input transducer for converting reference voltage. It will be suitably marked

Feedback Arrangement Tacho / Armature

Summing amplifier to receive inputs, reference signal and tachgenerator output. This amplifierwill have and adjustable again.

A DC Tacho- generator/speed sensor will be also used to indicate the motor speed in RPM.

Thyristor converter using single phase half

controlled converter to control DC motor through armature and power supply for field winding and electronic amplifier

Step Down Transformer Firing Circuit.

1:1 pulse Transformer.

7). POWER CIRCUIT:

Four SCR’s (600V/12A)

8.Pot for Open Loop

9.Pot for Closed Loop

10.Pot for Gain

11.Tachometer Panel type

12.Suitable protection for the electronic circuits and motor.

Aluminum Profile Modular System consisting of different type of modules.

Educational Bench Top Model with schematic / block diagram of the test circuit engraved on the panel.

Test points & measurement points brought out

and connected to 2mm plastic & BT15/30 terminals circuit setup for testing through

in reconnections of patch cards.

Complete illustrated manual covering brief theory of Equipment along with technical details and experimental procedures,

Connection diagrams will be supplied with experimental set up.

Technical Specifications:

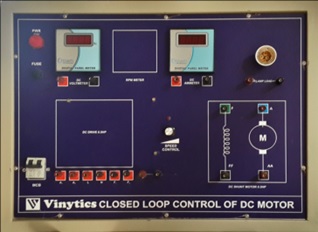

1)Digital Meters: Voltage & Current Measurement

2)Digital RPM counter

3)Double Pole MCB

4)LED Indicators

5)A.C. MOTOR:

AC Induction Motor 0.5HP, Capacitor

start 1phase 230V AC, 50Hz, 1440rpm,

TEFC, IP44, IC01, Class-B,

and Single Shaft Extension.

6) FIRING CIRCUIT:

Micro Controller based Firing circuit for precise control.Step Down Transformer Firing Circuit.

Firing Angle Display.Facility for firing angle control using a potentiometer

7). POWER CIRCUIT:

Two SCR’s (600V/12A) in Back to Back configuration

8) LOAD

Motor Mounted on MS Base with mechanical loading arrangement with pulley, belt, Spring Balance

DSO 2 channel 25Mhz, 500msps, 2.5 kpts

Aluminum Profile Modular System consisting of different type of modules.

Educational Bench Top Model with schematic / block diagram of the test circuit engraved on the panel.

Test points & measurement points brought out

and connected to 2mm plastic & BT15/30 terminals circuit setup for testing through

in reconnections of patch cards.

Complete illustrated manual covering brief theory of Equipment along with technical details and experimental procedures,

Connection diagrams will be supplied with experimental set up.

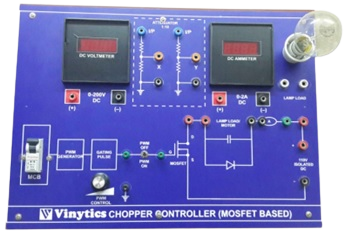

Technical Specifications:

1)Digital Meters: Voltage (0-300V) & Current Measurement (0-10A)

2)Digital RPM counter

3)TPN MCB

4)DOL Starter Three Phase

5)LED Indicators

6)A.C. MOTOR:

Type: AC Induction Motor,1 HP,3 Phase, 415V AC, 50Hz, 1440rpm, TEFC, IP44, IC01, Class-B, Single Shaft Extension.

CONTROL CIRCUIT:

The control circuit generates driver output for driving the MOSFET in chopper mode. The duty cycle can be varied from 0% to 90%. The frequency can be varied.

Soft start and soft stop is provided for driver output.

POWER CIRCUIT:

One MOSFET / IGBT (600V/25A)

3 phase bridge rectifier to convert 3-phase rotor supply to DC supply. An indicator is connected in series with the DC supply for smoothing of a DC. A Glass fuse is connected in series with the

DC supply.

An IGBT is provided for chopper control MOSFET is mounted on a proper heat sink. Snubber circuit is connected across

MOSFET for dv/dt. A fuse is also provided for protection.

All the points are brought out on the front panel for interconnection.

Six power Diodes (600V/12A) to rectify Wound Rotor generated AC Resistor for starting

Address List

- 12, Truck Market, Opp. R.K. Hospital, Near Mother Dairy Red Light , Pandav Nagar, Delhi-110092

-

+91 9899899166

+91 9871600331

+91 9868039427 -

vinyticsindia@gmail.com

www.vinytics.in